Bambu Lab Filament Support for PA / PET - Green

0.5kg - 1.75mm - Easy Support Removal - Recommended for PAHT-CF / PA6-CF / PET-CF / PA-GF - 65500

Bambu Lab Filament Support for PA / PET - Green

0.5kg - 1.75mm - Easy Support Removal - Recommended for PAHT-CF / PA6-CF / PET-CF / PA-GF - 65500

- Brand: Bambu Lab

- MPN: S03-G1-1.75-500-SPL

- Part #: INKBAM0003

- UPC:

- Brand: Bambu Lab

- MPN: S03-G1-1.75-500-SPL

- Part #: INKBAM0003

- UPC:

Features

Specifications

Reviews

Delivery & Pick-up

Returns & Warranty

Popular 3D Printer Filament & Resins

Bambu Lab Filament Support for PA / PET - Green 0.5kg - 1.75mm - Easy Support Removal - Recommended for PAHT-CF / PA6-CF / PET-CF / PA-GF - 65500

- Brand: Bambu Lab

- MPN: S03-G1-1.75-500-SPL

- Part #: INKBAM0003

Product URL: https://www.pbtech.com/pacific/product/INKBAM0003/Bambu-Lab-Filament-Support-for-PA--PET---Green-05k

Features

Downloads: Filaments TDS

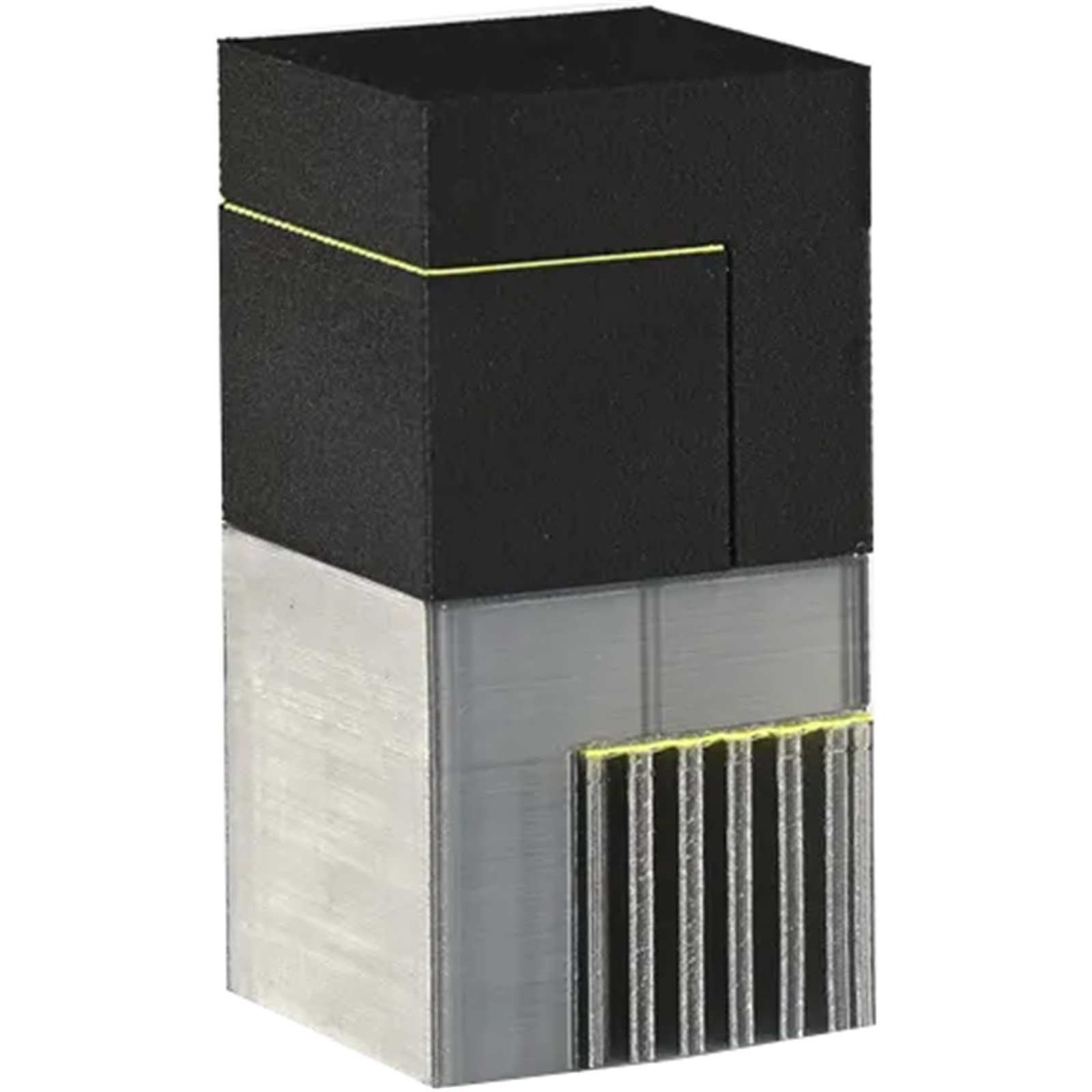

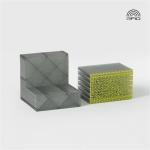

Support for PA/PET

- Easy removal by hand

- Perfect support interface

- Recommended for PAHT-CF, PA6-CF, PET-CF, PA-GF, etc.

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for Use

- ONLY used for support interface

- NOT used for printing models alone

- Dry out before use

- AMS compatible

- AMS lite NOT Compatible

- Enclosure Printers Required

RFID for Intelligent Printing

All printing parameters are embedded in RFID, which can be read through our AMS (Automatic Material System). Load and print! No more tedious setting steps.

Printing Tips

- Support for PA/PET needs proper drying before printing: recommended drying temperature is 80 ? for 8 hours in a blast drying oven, or 90 ? for 10 hours on heat bed. Learn more about filament drying. Please refer to Filament drying cover on WIKI.

- We recommend removing the support structures within 2 hours after printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to ease the removal.

Learn more different filaments comparison on Bambu Filament Guide >>

Specifications

Recommended Printing Settings

Drying Settings (Blast Drying Oven)

80C,12h

Printing and Keeping Container's Humidity

< 20% RH (Sealed, with Desiccant)

Nozzle Temperature

280 - 300C

Bed Temperature (with Glue)

80 - 110C

Printing Speed

< 100 mm/s

Physical Properties

Density

1.17 g/cm³

Vicat Softening Temperature

N / A

Heat Deflection Temperature

N / A

Melting Temperature

255C

Melt Index

29.2 ± 2.1 g/10 min

Mechanical Properties

Tensile Strength

N / A

Breaking Elongation Rate

N / A

Bending Modulus

N / A

Bending Strength

N / A

Impact Strength

N / A